| ||||||||||||||||||||||||||||||||||||

LAUNCH OF THE N1

In the photo above, you can see part of the frontage of the site. The large vehicle assembly building is behind the green awning and the Ryder truck can be seen to the right of it. And, most spectacularly, is the N1 painting done by Mare McMurray for the launch! (See a close up.) PREPARATIONAll of the rocket building had been done by the time we got out to the launch site (although some of it just barely).

Above you can see the inside of the assembly building (shelter) as things were unpacked. David Wilkins and just arrived and we were getting ready to start rocket preparations.

Here is another view of the shelter, after we'd started to work on prepping the rocket. Chet is starting to wire the sustainer motors.

And you can see the active flight electronics. We flew 9 G-Wiz units in total:

We also flew a Missile Works WRC² R/C unit for sustainer ignition and back-up sustainer deployment.

Above you can see Larry hooking up the ejection charges for one of the recovery systems. We had six parachute cannon in the rocket:

(Each parachute was a 10' SPECTRAchute hemispherical parachute with red and gold bands.) Since each parachute cannon had redundant deployment, we had two charges in each cannon. The single parachute cannons and 5g charges and the double cannon had 10g charges for a total of 70g of black powder.

As motor guy, Chet had the responsibility for installing all 42 motors. In the pictures above, you can see him installing booster motors, sustainer motors and with motor installation done.

Tom Cloud ("Bubba von Braun") hung out with us and was a huge help with the rocket. In the picture above, you can see he and Larry starting to work on the booster.

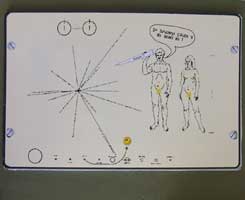

Bob made up two plaques for the rocket. The first was a take-off on the Surveyor plaque and the second had all the team members' names in Cyrillic characters (sort of).

The rocket was far too large to assemble and measure the C.G. as a whole. Instead, we weighted and measured the C.G. of each stage separately and them worked out the C.G. of each flying unit based on weighted averages. In the picture above, you can see us balancing the booster to find the C.G.

On Friday night, we had the C.G. and update the RockSim file with the final weights and C.G.s for all stages. We decided to add another 25# to the nose to give us a larger margin of stability when the sustainer was flying alone. (You can download our RockSim 5 file to see for yourself.) In the picture above, John is drilling holes in the wooden escape tower for lead shot. RAISING THE ROCKETWe reconvened on Saturday morning at 6:00am, after two hours of sleep, to set the rocket up for the promised 8:00am launch time. Big projects are always late, but we had taken every precaution to prepare the rocket to go and we intended to make the time. (Because of the lack of fins and three stages, we had to launch before the wind came up.)

Here you can see us out at the launch site (1500' from the flight line) with the launcher base and the rocket parts laid out and ready for assembly.

The rocket was quickly assembled and raised to an upright position on the launcher base. Note that because the launch rod was a bit too flexible, we had to stabilize the sustainer with ropes at the second interstage and the escape tower.

In this picture, you can see the ropes stabilizing the sustainer and the four perimeter blocks. These were added at the last minute and Tom Cloud sacrificed one of his beautiful hand-made fiberglass tubes to make them. (That's a 12' ladder to the left of the rocket.)

Chet was the lucky one who got to arm the stages once the rocket was upright. Here you can see him arming the sustainer while the rest of us mill around. Each stage had arming for the recovery electronics and shunts for the second stage and sustainer ignition. We used no switches. Instead, a wire came out from each unit to the outside. The leads were stripped and twisted together, then pushed back into the vent tubes. This system was simple and reliable and all units armed properly. There we were with a rocket with 42 motors and 70g of black powder armed and ready to go. Not to mention with a height of 22' and weighing over 200#. In particular, there was no way that Chet could escape since he was on top of a 12' ladder right next to the rocket. His bravery and dedication definitely merit the Order of Lenin!

Above you can see Chet and Ed hooking up the igniters for the booster motors. The six central K1050s were launched using one system and the 24 perimeter G38s were lit with another. That's a lot of igniters! THE LAUNCHOur goal was to launch at 8:00am on Saturday and at 8:15 we were ready. The rocket was ready ahead of time and assembling and arming the rocket went smoothly. We made this announcement before the launch: "We have a model of the Soviet moon rocket, the N1. During the Apollo program in the 1960s, the Soviets also had their own moon program. The vehicle for this mission was the N1, mostly designed by Korolev. They flew four N1 vehicles, all of which had engine or structural failures. The program was abandoned in 1974 and the remaining airframe pieces became storage sheds. "The N1 stood 350 feet tall and was 55 feet in diameter at the base. It had 42 engines burning kerosene in liquid oxygen. The lift-off weight was 2860 tons. The total impulse of the first three stages was 7.4 billion Newton-seconds. (That would 723,000 full M motors.) "That was the 1960s. Now, for the new millennium, AERO-PAC conceived a group project: "Moon Race 2001." This was to be a 1/16 scale Saturn V (the U.S. moon vehicle) vs. an N1. We would drag race them at LDRS. Well, the American team never got their rocket built so the N1 wins by default. Be sure to check out the web site at www.moonrace2001.org! "Our N1 stands 22 feet tall and is more than 3½ feet in diameter at the base. Our model has the prototypical number of motors (for the 3 stages). The first stage has 24 G38s in a ring around the perimeter and 6 K1050s in the center. The second stage has 8 H124s in a ring and the third has 4 H124s. The rocket will recover in 4 pieces: the booster, the 2nd stage, and the sustainer recovers in two sections.

"We want to thank Peter Alway for his wonderful book Rockets of the World. Also, we'd like to thank Loc/Precision and FibreGlast for filling many last-minute orders. OK, let's go! We have the Soviet anthem and a countdown in Russian for you." The soundtrack can be downloaded here. First, the Soviet anthem starts. Then, 30 seconds into it, the countdown begins in Russian. (Countdown spoken by Vladimir Abdilov.) The photo sequence below (by Ed Hackett) is worth a thousand words.

The first picture shows the smoke charges which ignited 20 seconds before the motors, during the anthem. The other three shots show the actual liftoff. (Click on the pictures for larger versions.)

The sequence above was taken by Chris Atteberry. (Again, click on the pictures for larger versions.)

This picture, showing the crowd and the smoke trail, was taken by John Bohner.

The photo on the right was taken by Jeff Stai and really shows the power of all those motors with the flames glowing through the smoke. The flight was perfect, straight up and steady. The second stage staged properly at booster burnout and the third stage was ignited manually very shortly thereafter (Chet's magic again). The booster reached 924 feet, the second stage reached 1342 feet and the sustainer reached 1652 feet. The entire flight with all the events was easily visible from the ground. Truly spectacular! The many parachutes (3 for the booster and 2 each for the second stage and sustainer) all deployed, but did not inflate properly. Partly because the shroud lines were taped and partly because there was not enough descent time.

RECOVERYBecause the 'chutes never completely opened, all pieces of the rocket hit hard. The booster even bounced about three feet into the air! The parachutes were 10' hemishperical shapes from SPECTRAchutes. They were made with alternating red and gold stripes which would have looked wonderful fully inflated. (The parachutes didn't inflate fully because we taped the shroud lines for packing and there was not enough distance to fall to break all the tape.)

Because the rocket didn't go very high (1600'), the parts were all recovered very close to the launch pad. In the photo above, you can see the booster back on the ground.

All those blackjack motors make quite a mess as you can see in the picture above of the aft end of the second stage.

The booster was too large to fit into any of the cars, so we took the Ryder truck out to pick it up. You can see some of the landing damage (one of the outer nozzles broken off).

In the picture on the right, you can see the booster and second stage stacked on top of each other back in camp (without the interstage). Note the black marks from the second and third stage blackjack motors. On the ground to the right of the booster, you can see the forward end plate. This plate jarred loose when the booster hit. (The three large holes are for the parachute cannon.) The rocket survived amazingly well for such a large rocket and such a hard landing. Other than some cracks in the fiberglass, one of the booster conduit details broke off, and the breaking off of the top plate, the booster is in pretty good shape. Most impressively, the large base plate survived intact with just one nozzle detail broken off. The second stage is in even better shape with no major damage. The sustainer faired the worst. The wooden escape tower was driven back into the rest of the rocket when the sustainer landed, pretty well destroying the forward half of the sustainer. The aft half was fine. It seems that the rocket faired so well because of its light weight and because of the Styrofoam. The foam didn't add much weight, but provided good support for the skin and the plates. In fact, the booster bounced when it hit, instead of shattering. The numbers: the booster flew to 924', the second stage to 1342' and the sustainer to 1651'. We had expected about 3000' of altitude, but weren't able to simulate the interstages or external conduits properly. Also, we added nose weight on site to a rocket that was heavier than predicted. We also had two motors fail. One of the booster K1050s split the fiberglass tube and dumped out its contents shortly after ignition. (This lost us 1/7th of our booster thrust.) Also, one of the second stage H124s blew off the nozzle.

Above you can see the summary screen from one of the two G-Wiz MCs we flew.

The MC is a new recording unit coming soon from G-Wiz partners.

Click on the tabs "Altitude Graph" and "Acceration Graph"

to see some of the other screens.

A couple of friends from work came down to see the launch. Above you can see Andy Mazur saluting in his Soviet uniform. There also extra pictures and videos for those who want to see more. The rocket could be repaired and flown again, but the LDRS flight was its mission and that was accomplished spectacularly. The booster rests in the Rocketeer Media museum and the other parts are currently in the warehouse in which it was built. Thank you N1, you did us proud! | ||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||